Black 320g 400g Lightweight Mat Carbon Fiber Veil Mat CSM High Strength

| Place of Origin | CHINA |

|---|---|

| Certification | ISO 9000 |

| Model Number | EMK300/C20 |

| Minimum Order Quantity | 500kgs |

| Price | negotiatable |

| Packaging Details | The mat is wrapped in plastic film and put in a woven bag. It is either in bulk or loaded in pallet at delivery. 16 rolls a pallet, 10 pallets for a |

| Delivery Time | 7 DAYS |

| Payment Terms | T/T, L/C |

| Supply Ability | 20MT A WEEK |

| Material | Fiberglass Chopped Strand Mat And Carbon Fiber Veil | Color | Black And White |

|---|---|---|---|

| Width | 150-3200mm | Character | High Tensile And Smooth Surface |

| Weight | 330g-480g | Combine Type | Stitch Knitted |

| Resin Type | Unsaturated Resin And Other Type | Application | Wide Usages In FRP Industry |

| Highlight | Black 320g fiberglass veil mat,CSM 400g mat carbon fiber,CSM carbon fiber veil |

||

HIgh tensile strength light weight combo mat, CSM and carbon fiber mat 320g/ 400g, compatiable with all types of resin

Introduction:

Carbon fiber stitching combo mat is to take carbon fiber mat as the base layer, and its above is not evenly spread glass fiber short-cut, and then coil structured them.

Specifications:

|

Product NO. |

Overall Weight (g/m2) |

Chopped Roving (g/m2) |

Fiberglass Surface Mat (g/m2) |

Width (mm) |

| EMKS 330 | 330 | 300 | 30 | 150 - 3200 |

| EMKS 430 | 430 | 400 | 30 | 150 - 3200 |

| EMKS 350 | 350 | 300 | 50 | 150 - 3200 |

| EMKS 450 | 450 | 400 | 50 | 150 - 3200 |

| EMKS 380 | 380 | 300 | 80 | 150 - 3200 |

| EMKS 480 | 480 | 400 | 80 | 150 - 3200 |

Features:

● Carbon fiber veil can make the surface of the product with conductive property.

● Good designablity, thickness of the fiber layer is optional.

● Solve the problems of easy break, wrinkle and other symptoms when the carbon mat is separately moulding.

Application:

● Compatiable with reinforced unsaturated polyester resin, vinylester resin, epoxy resin, phenolic resin and polyurethane resin etc.

● Forming process includes pultrusions, winding, hand lay-up etc.

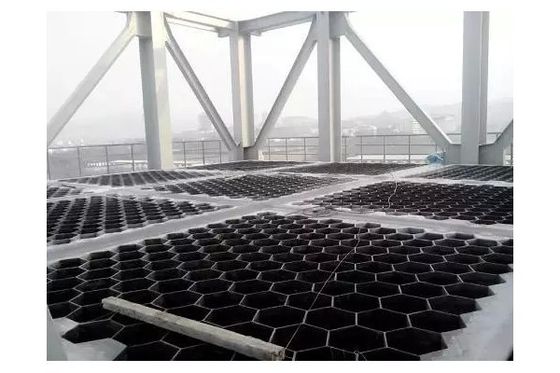

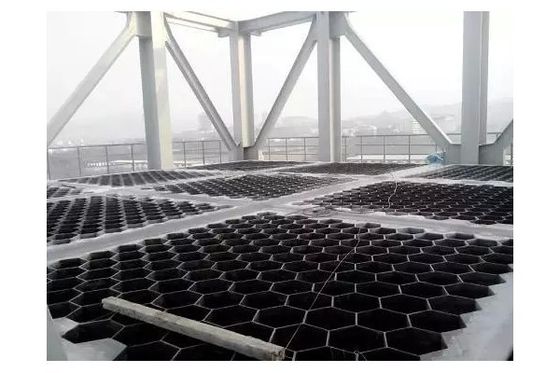

● They typical end-use applications are anode tube or panel for wet dust collector.