Woven Roving Stitched Fiberglass Surface Mat 600g/M2 EMKW 800 900

| Place of Origin | CHINA |

|---|---|

| Certification | ISO 9000 |

| Model Number | EMK225/W400 |

| Minimum Order Quantity | 500kgs |

| Price | negotiatable |

| Packaging Details | The roll is wrapped up with plastic film and then packed in a woven bag. Usually 9 rolls a pallet, and 10 pallets in a 20' container. If without pallet package, a container could hold about 10 MT |

| Delivery Time | 7 DAYS |

| Payment Terms | T/T, L/C |

| Supply Ability | 20MT A WEEK |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Non-metallic Product | E Glass Woven Roving And Chopped Strand Mat | Color | White |

|---|---|---|---|

| Width | 1600mm | Character | High Tensile And Easy Wet-out |

| Resin | Unsaturated Resin And Other Type | Application | FRP Boat, Panel Etc. |

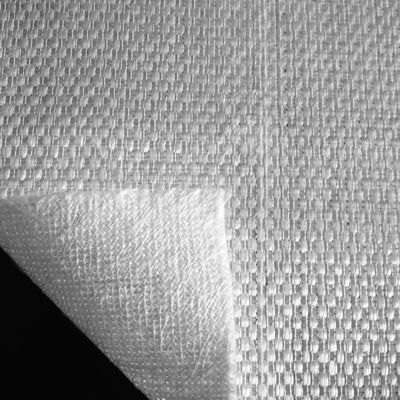

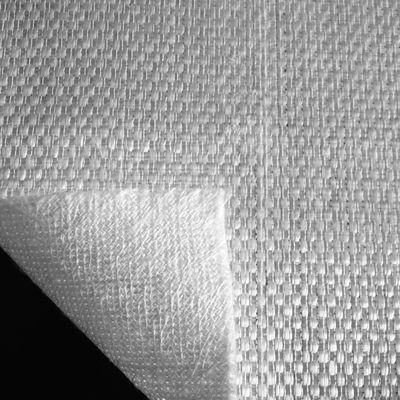

| Highlight | 600g/m2 Fiberglass Surface Mat EMKW 800,EMKW 800 woven roving mat,EMKW 900 stitched fiberglass mat |

||

Woven roving stitched combo mat with high tensile strength comptatiable with all types of resin used in pultrusion FRP

Introduction:

Woven roving stiched combo mat is the mat of woven roving as the base layer, above uniforming the non-directional glass fiber short-cut, and then stitch them in coil structure.

Specifications:

| Product NO. |

Overall Weight (g/m2) |

Chopped Roving (g/m2) |

Woven Roving (g/m2) |

Width (mm) |

| EMKW 600 | 600 | 200 | 400 | 150 - 2400 |

| EMKW 700 | 700 | 300 | 400 | 150 - 2400 |

| EMKW 800 | 800 | 200 | 600 | 150 - 2400 |

| EMKW 900 | 900 | 300 | 600 | 150 - 2400 |

| EMKW 1000 | 1000 | 200 | 800 | 150 - 2400 |

| EMKW 1100 | 1100 | 300 | 800 |

150 - 2400 |

Features:

● Both the orientation of the woven roving and the multi-directional of the chopped strand mat

● Uniform thickness, no hairiness and no stain

● Regular interspaces is in favor of flow and wet-out of resin

● Felt is wrap-proof, rolling resistant and high operation efficiency

Application:

● Compatiable with reinforeced unsaturated polyester resin, vinlylester resin, epoxy resin, phenolic resin and polyurethane resin etc.

● Forming process includes pultrusion, hand lay-up and RTM etc.

● The typical end-use applications are pultruded profile, nacelle cover, anode tube, FRP boat hull, panel etc.