All Products

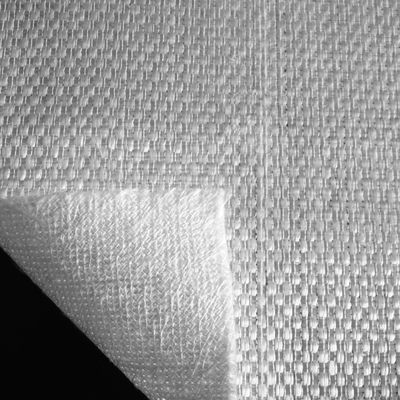

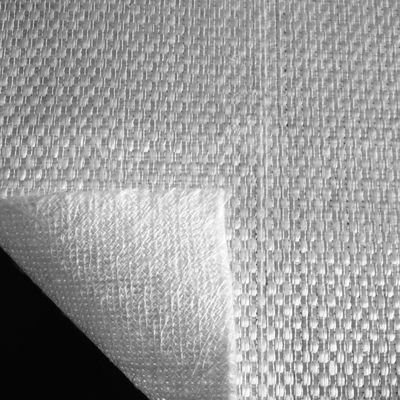

Anti Aging E Glass Fiberglass Woven Roving Adding A Layer Of Chopped Strands

| Place of Origin | CHINA |

|---|---|

| Certification | ISO 9000 |

| Model Number | EMKW550-830mm |

| Minimum Order Quantity | 500kgs |

| Price | negotiatable |

| Packaging Details | The roll is wrapped up with plastic film and then packed in a woven bag. Usually 9 rolls a pallet, and 10 pallets in a 20' container. If without pallet package, a container could hold about 10 MT |

| Delivery Time | 7 DAYS |

| Payment Terms | T/T, L/C |

| Supply Ability | 20MT A WEEK |

Product Details

| Material | E Glass Woven Roving And Chopped Strands | Color | White |

|---|---|---|---|

| Width | 830mm | Character | Easy Wet-out And Smooth Surface For FRP Product |

| Resin Type | Unsaturated Resin And Other Type | Application | Auto Housing |

| Specification | 550g/m2 | Weight | 24kgs/roll |

| Highlight | Anti Aging Fiberglass Woven Roving,Chopped Strands E Glass Woven Roving,Unsaturated Resin Fiberglass Woven Roving |

||

Product Description

E Glass Fiberglass woven roving adding a layer of chopped strands with better quality on strength and anti aging of finished products

Its features:

- Solve the problems of easy break, wrinkle and other symptoms when the polyester veil is separately moulding

- Reduce the workload of laying, improve production efficiency.

- Fiberglass surface mat absorbs resin fast, the product surface is smooth.

Application:

- Compatiable with reinforeced unsaturated polyester resin, vinlylester resin, epoxy resin, phenolic resin and polyurethane resin etc.

- Forming process includes pultrusion, RTM, continuous plate process etc.

- The typical end-use applications are PU pultruded profile, antenna radome, cable tray, panel etc.

Specifications:

|

Product NO. |

Overall Weight (g/m2) |

Chopped Roving (g/m2) |

Fiberglass Surface Mat (g/m2) |

Width (mm) |

| EMKS 330 | 330 | 300 | 30 | 150 - 3200 |

| EMKS 430 | 430 | 400 | 30 | 150 - 3200 |

| EMKS 350 | 350 | 300 | 50 | 150 - 3200 |

| EMKS 450 | 450 | 400 | 50 | 150 - 3200 |

| EMKS 380 | 380 | 300 | 80 | 150 - 3200 |

| EMKS 480 | 480 | 400 | 80 | 150 - 3200 |

Recommended Products