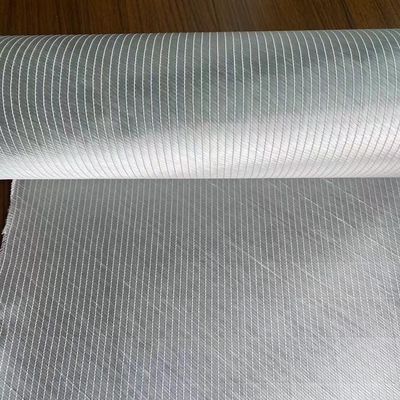

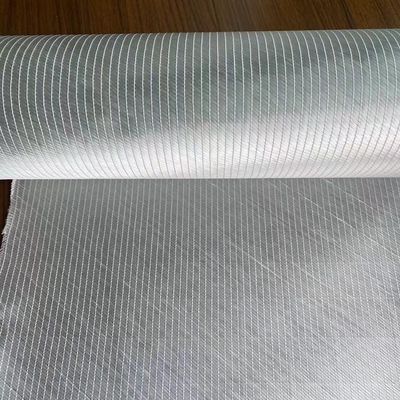

Vinyl Ester Resin Compatible +45/-45° Fiberglass Biaxial Fabric For FRP Reinforcement

| Place of Origin | CHINA |

|---|---|

| Certification | ISO 9000 |

| Model Number | ELT650-1270 |

| Minimum Order Quantity | 500kgs |

| Price | negotiatable |

| Packaging Details | The roll is wrapped up with plastic film and then packed in a woven bag. Usually 9 rolls a pallet, and 10 pallets in a 20' container. If without pallet package, a container could hold about 10 MT |

| Delivery Time | 7 DAYS |

| Payment Terms | T/T, L/C |

| Supply Ability | 20MT A WEEK |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Fiberglass | Color | White |

|---|---|---|---|

| Texture | +45°C And -45° Weaving | Width | 1270mm |

| Resin | Unsaturated Resin And Other Type | Application | Transportation Equipment |

| Weight | 650g | ||

| Highlight | FRP Reinforcement Biaxial Fabric,Vinyl Ester Resin Fiberglass Biaxial Fabric,FRP Reinforcement Fiberglass Biaxial Fabric |

||

Strong +45/-45°Fiberglass Biaxial Fabric For FRP, Reinforcement With A Layer Of Chopped Strands Easy Wet Out Resin

Introduction:

Fiberglass biaxial fabric is a cloth in which the roving is arranged in a two-way direction at 90º (transverse) and 0º (longitudinal), and then stitched with a coil structure. It can be stitched two-way layer yarn with chopped strand mat, polyester surface felt, fiberglass surface felt, carbon fiber surface felt, etc., processed into various types of composites fabric to obtain specific performance.

Features:

● No binder content, good wet out of resin

● Provide mechanical strength of the product i multi direction

● Fiber straight arrangemet, max. usage of fiber strength

● Interspaces between the fibers are small, effectively improve the impact resistance of products

Application:

● Compatiable with reinforeced unsaturated polyester resin, vinlylester resin, epoxy resin, phenolic resin and polyurethane resin etc.

● Forming process includes vacuum infusion molding, pultrusion, hand lay-up, RTM etc.

● The typical end-use applications are FRP boat hull, wind power blade, sports equipment, pultruded profile and auto body etc.